In situations where accurate results and precise control can lead to the next biomedical breakthrough, pipetting with repeatable and verifiable processes is critical.

Since the first piston driving pump system arrived in the 1950s, almost every year brings new capabilities to pipettes that help scientists, researchers, and technicians improve their lab workflows.

The global pipette market size exceeded $1.4 billion in 2019, according to analysts. Likewise, increased investment in biotechnology and pharmaceutical research will see the pipette industry grow by a 3.7% compound annual growth rate (CAGR) until 2025. Key market drivers include increased demand for molecular biology applications and better product designs that extend new instruments' capabilities. For more information and a comprehensive list of all pipetting terms and normative references, see ISO 8655 Standard, Part 1.

Pipetting Terms for Modern Lab Technicians

From single to multichannel micropipettes, manual or electronic covering a wide range of volumes, the industry continues to develop products with greater accuracy and for increased comfort.

To keep up with the latest developments, techniques, and best practices, here's a handy glossary of pipetting terms that every lab technician should know.

Different Pipette Types and Working Principles

Two main pipette types are available depending on your application.

When samples are aqueous, and you're doing general lab work, an air-displacement pipette will suffice. If the samples are volatile, viscous, corrosive, hot or cold, radioactive or contaminating, you'll need a positive-displacement pipette.

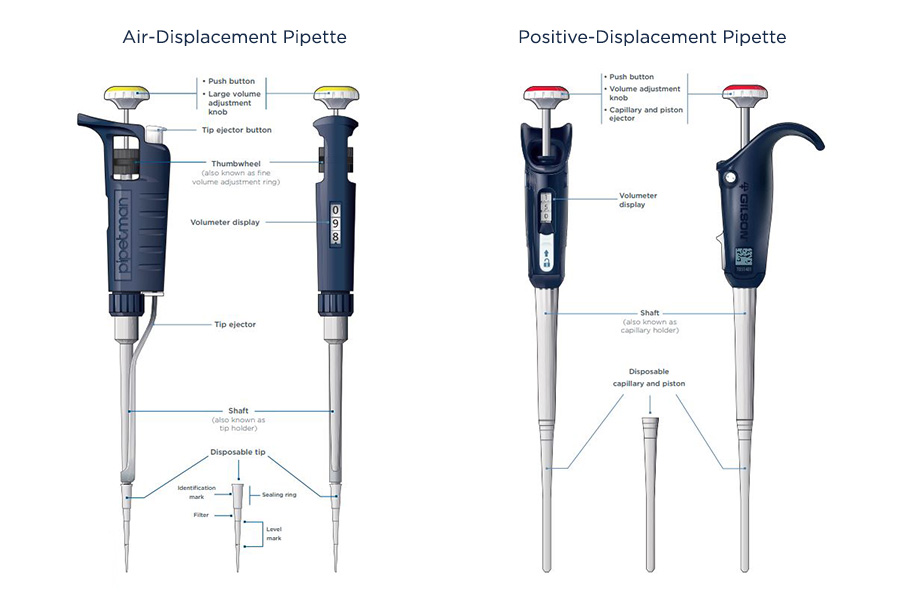

- Air-displacement pipette – The piston (integrated in the lower part of the pipette) moves the liquid under the action of an air cushion (also called dead volume) between the pipette and the liquid sample.

- Positive-displacement pipette – The piston is part of the specialized disposable tips called capillary piston (CP) tips and is in direct contact with the liquid. CP tips replace the air cushion between the liquid and piston, so it does not affect volume accuracy regardless of the fluid's properties.

Figure 1. Diagram of an air-displacement pipette (left – PIPETMAN®) and positive-displacement pipette (right – MICROMAN® E)

Working with either an air-displacement or a positive-displacement pipette follows a similar process, although devices have different working principles. An air-displacement pipette aspirates samples equal to the volume of air displaced during operation. A general recommendation is to use an air-displacement pipette with aqueous and non-viscous samples.

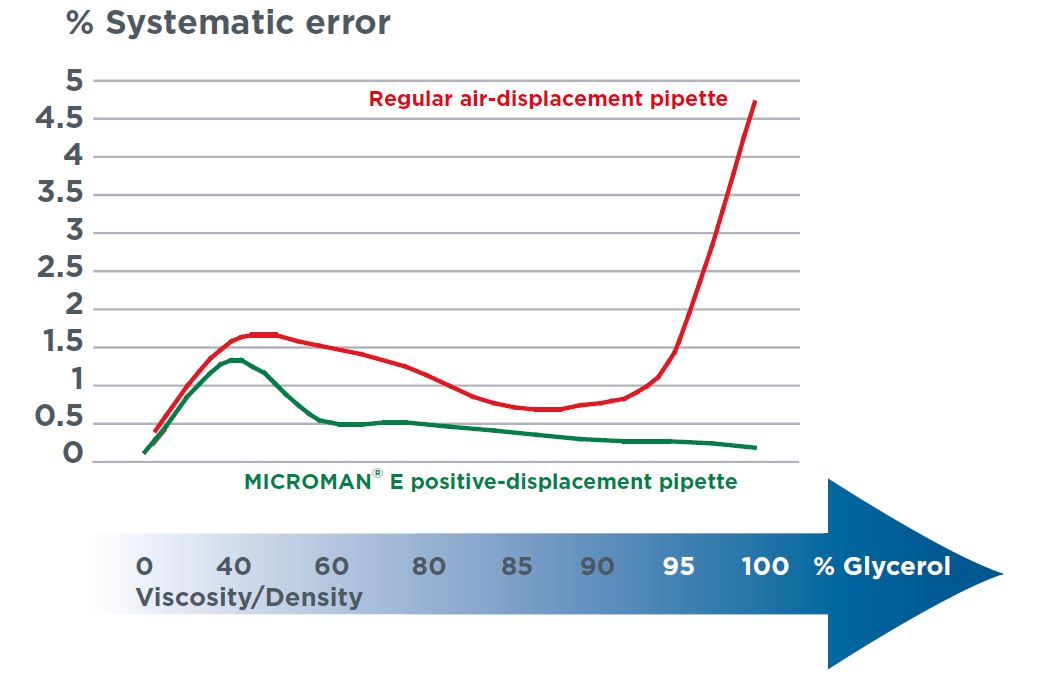

Temperature and atmospheric pressure and the specific weight and viscosity of the solution can affect the performance of air-displacement pipettes. In positive-displacement pipettes, the piston being in direct contact with the liquid ensures a consistent aspiration force regardless of the sample's physical properties. The disposable capillary piston prevents contamination since it makes direct contact with the sample, protecting both the user and the pipette.

The standard pipetting steps for both types are:

- Fitting the tip – Selecting and matching the correct pipette tip on the instrument with options including filtered, non-filtered, sterile, or non-sterile

- Set volume – Using the volume adjustor to set the required amount of volume for aspiration

- Prepare for aspiration – Pressing the push-button to the first stop position to descend the piston to the required level

- Aspirate the sample – Immersing the pipette tip into the sample and smoothly releasing the push-button to aspirate the exact volume as per the set volume

- Dispense the sample – Repressing the push-button to the first stop to dispel the sample from the pipette tip or capillary

Modes of Operation for Different Pipettes

Depending on the application, you can pipette in either forward or reverse mode.

Forward mode – Standard method of pipetting used in both air-displacement and positive-displacement pipettes

For air-displacement pipettes:

- Perform the standard pipetting steps described above (Working principle)

- Purge – Wait one second, then depress the plunger to the second stop position. This purge stroke removes any remaining sample from the tip. Remove pipette tip end from sidewall by sliding it up the wall.

- Home – Let the plunger move back up to the rest position.

- Eject – To avoid touching contaminated tips, hold the pipette over the waste container, and press the tip ejector push button.

For positive-displacement pipettes:

- Perform the standard pipetting steps described above (Working principle). Unlike air displacement pipettes, positive-displacement pipettes do not have any air cushion, and there is no purge needed.

- Eject – Press the plunger all the way down to the second and last stop, ejecting the capillary and piston without hand contact.

Reverse mode – Only possible with air-displacement pipettes for slightly viscous liquids. Pipetting in reverse mode has steps in common with the forward mode but uses the purge stroke during preparation. During aspiration, you add an amount of liquid equal to the amount of purged air. This amount compensates for the liquid that remains inside the tip during dispensing steps.

- Preparation – Smoothly depressing the plunger to the second stop position (purge) while holding the instrument vertically.

- Aspiration – Immersing the pipette tip in the sample and allowing the plunger to move back up to the resting position smoothly.

- Dispense – Placing the tip at an angle (10° to 45°) against the inside wall of the receiving vessel and depressing the plunger smoothly to the first stop position.

- Re-aspirate – If you can reuse the pipette tip for the same sample, maintaining the plunger in the intermediate position for subsequent immersion for the next pipetting cycle.

- Complete purge – If the pipette isn't going to be reused, depress the plunger to purge position over an appropriate waste container.

- Eject – To avoid touching contaminated tips, hold the pipette over the waste container, and press the tip ejector push button.

- Home – Allowing the plunger to return to the rest position before restarting the process.

Everything You Need to Start Your Experiments

Choose our cost-effective, bundled PIPETMAN® L starter kit for everything you need to start your experiments. Our starter kits include pipettes, tips and tip ejectors, pipette holders, Gilson’s Guide to Pipetting, and our two-minute inspection poster.

SHOP STARTER KITS

Other Pipetting Terms

In addition to the above, you'll also need to know the following pipetting terms.

- Accuracy – Describes the closeness of agreement between the measured quantity and true quantity of the measurand. Accuracy is a qualitative concept.

- Precision and repeatability – Indicates the closeness of agreement between indicated volume and the measured quantity using a repeatable pipetting process under specified conditions. For pipettes, precision refers to a within-series group of data, and therefore to repeatability.

Note: Accuracy and repeatability describe the performance of the pipette.

- Measurand – The specific quantity value of sample volume you intend to measure.

- Air cushion – The volume of air located between the lower part of the pipette piston and surface level of the sample—also called the dead volume.

- Aliquot – The measured portion of multiple samples of a homogeneous entity.

- Sample (or test sample) – The appropriate representative part of a liquid to be analyzed.

- Sample carryover – The portion of the sample retained in the instrument after sample delivery that may affect subsequent samples. Carryover from a positive-displacement pipette is less when compared to an air-displacement pipette.

- Nominal volume – For variable volume pipettes, the nominal volume is the upper limit of the pipette's designated volume range. For fixed volume pipettes, the nominal volume is the fixed volume of liquid that can be aspirated and dispensed.

- Nominal value – Rounded value that provides guidance for a measuring system of the instrument and its appropriate use.

- True value – The value obtained from a perfect measurement instrument.

- Working range – Specified conditions for optimal performance of the instrument, including total volume, temperature, and ambient conditions.

The following errors may arise during your pipetting process.

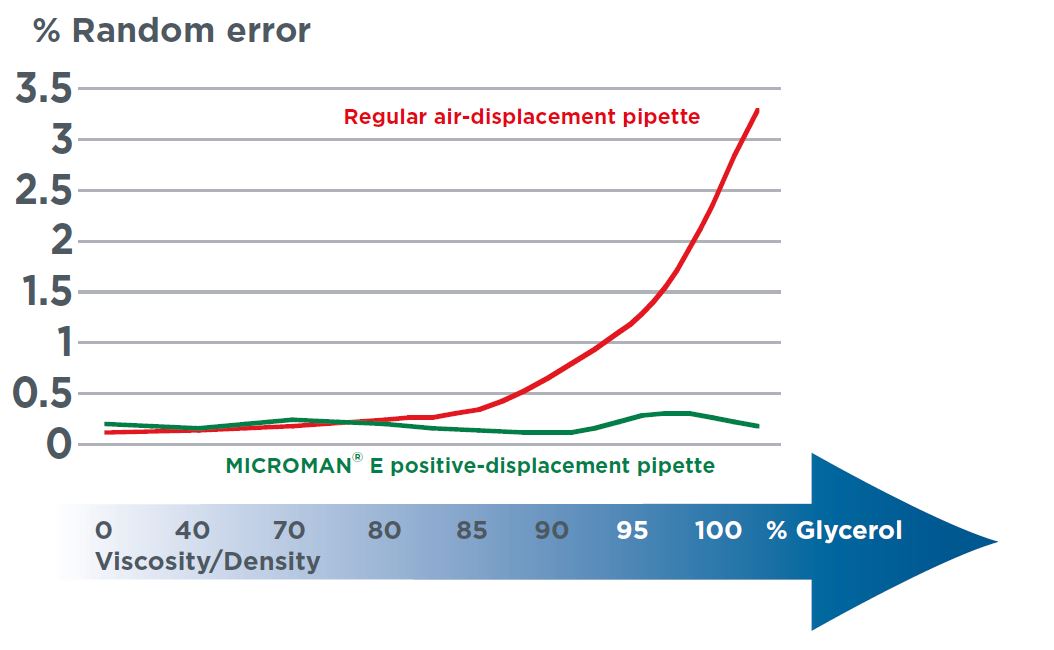

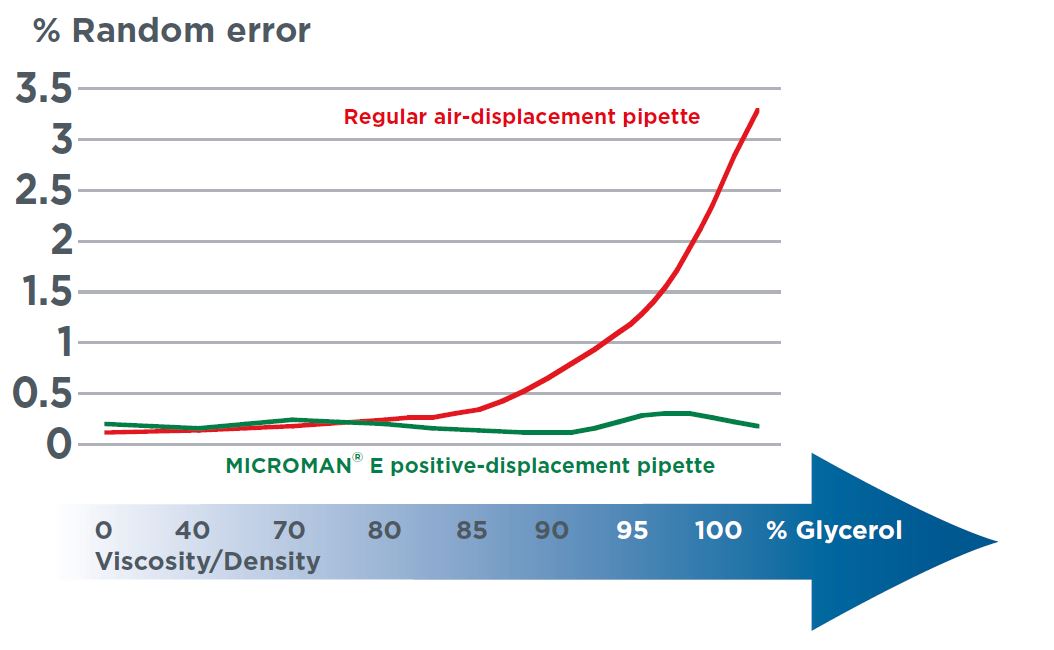

- Random error – Occurs when the measured component provides unpredictable variances in subsequent replicate measurements.

- Measurement error – The difference between a measured quantity value and a reference quantity value.

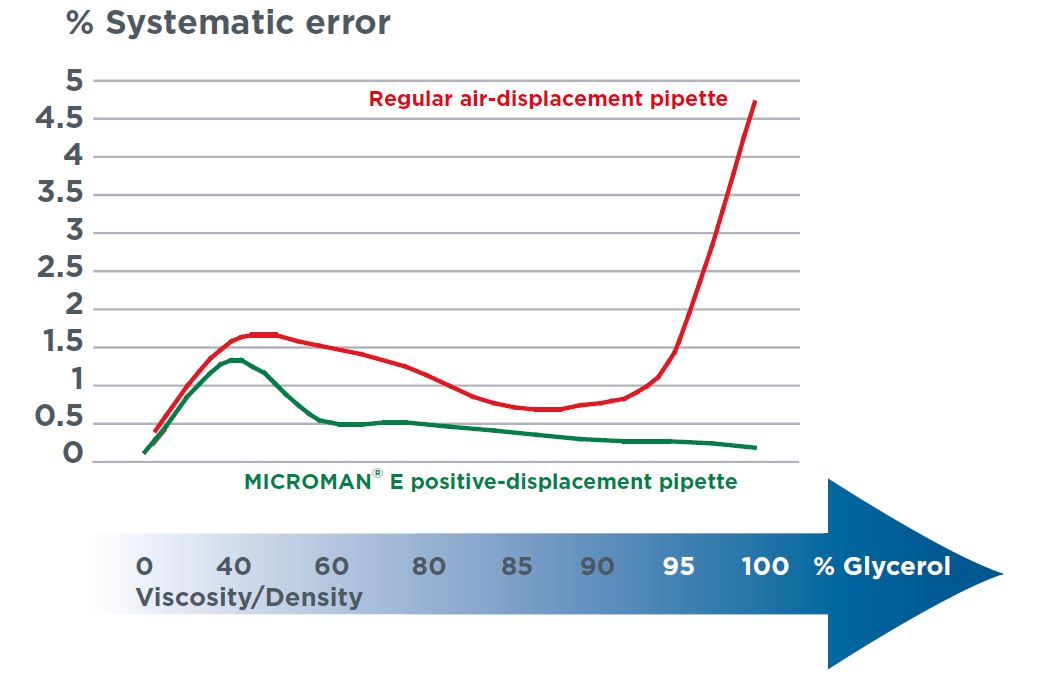

- Systematic error – If replicate measurement differences remain constant or vary in a predictable manner.

Figure 2. Systematic Error (%) when using a MICROMAN® E positive-displacement pipette vs. a regular air-displacement pipette

Figure 3. Random Error (%) when using a MICROMAN® E positive-displacement pipette vs. a regular air-displacement pipette

Establishing a Repeatable and Accurate Pipetting Process with Ergonomic Pipettes from Gilson

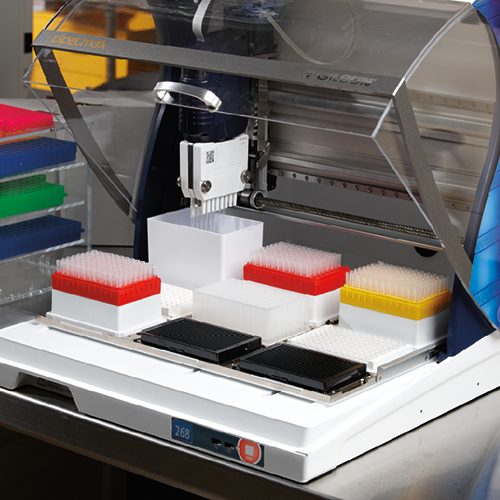

Gilson has a range of manual and electronic pipettes and complete pipetting systems to help lab technicians improve accuracy and provide repeatable results. Our multichannel pipettes allow transferring 8 or 12 samples in a single step, while a motorized pipette system will reduce user-to-user variability.

No matter your lab's workflow, Gilson has a pipette solution ideal for your processes and required volumes. You can read more about our pipettes' capabilities in this guide.

If you need additional information about Gilson's range of liquid handling systems, contact us today.