A generic workflow for solid phase extraction (SPE) goes through several consecutive steps before you can analyze the sample. We recently hosted a webinar on the required process for labs that want to automate and transition from a manual protocol.

During the webinar discussion, we focused on food and environmental testing as the primary example. However, these steps also apply to other complex matrixes since SPE is widely used because of its high selectivity and its high applicability to numerous types of analytes and matrixes.

SPE Objectives

A typical SPE process is based on a selective partition of the compounds of interest between a solid phase (sorbent) and a liquid phase.

Researchers and analytical laboratories can use an SPE workflow to isolate compounds from complex matrixes and recover them into a pure solvent. This isolation/clean-up process eliminates not only the matrix effects that would negatively impact the robustness of the analytical system (e.g., injection of killer substances like pigments) and the reliability of the results (e.g., ion suppression in MS detection), but also can concentrate analytes into a small volume of solvent.

A Typical SPE Workflow

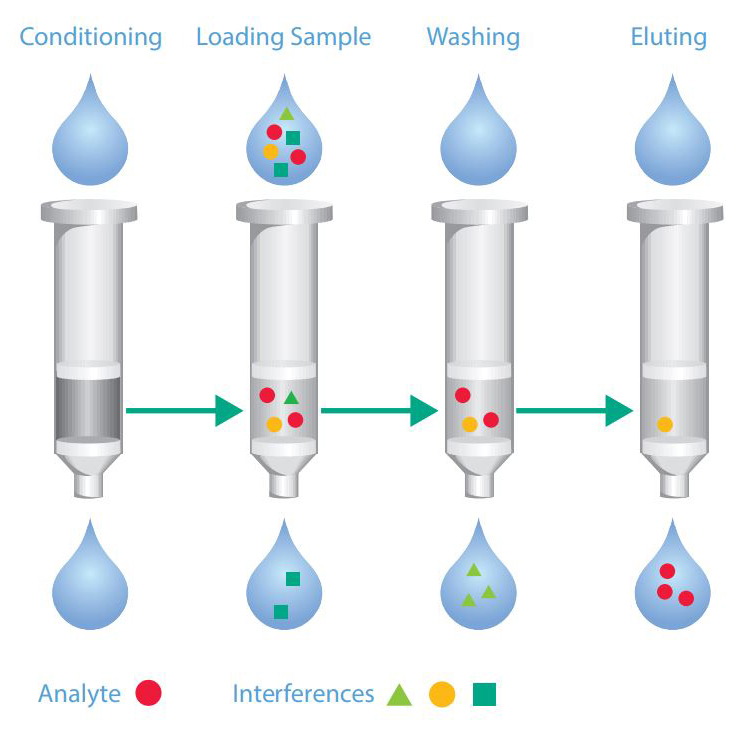

A typical SPE workflow is divided into four consecutive key SPE steps :

- Conditioning to regenerate the sorbent and prepare future retention of analytes

- Loading sample to isolate the analyte quantitatively on the solid phase and discard the matrix

- Washing to remove residual interferences and prepare the future elution

- Eluting to recovery quantitatively the analytes from the cartridge into a pure solvent

Figure 1. A Typical Four-Step SPE Method

Food Safety and Solid Phase Extraction Automation

In food safety, achieving analytical regulation requirements for reporoducibility, limit of detection, and quantification may be challenging due to sample matrixes' complexity.

Because of its versatility and selectivity, SPE is widely used in this field by isolating and cleaning up semi-volatile and non-volatile analytes before analysis from any complex liquid samples or liquid extracts of solid samples. Solid samples are usually ground, and then the compounds of interest are extracted using techniques like liquid extraction, salting-out (QuEChERS), pressurized liquid extraction, or microwaving. Then, the compounds of interest are ready to be isolated from other co-eluting interferences by SPE. Liquid samples are usually processed in a single step that combines extraction and isolation, as the compounds of interest are already in a solution.

Why Automate SPE for Analysis of Complex Matrixes?

Enhanced Performance & Increased Throughput

SPE is an excellent sample preparation technique to improve the reliability of the analytical results, especially in the case of complex matrices like foods and beverages. However, it requires perfect control of some critical parameters to ensure accuracy and reproducibility (drying state of the sorbent, volumes and flow rates) in order to:

- Keep the packing material moist during the initial conditioning steps, especially with the silica-based sorbent, to avoid channeling and unreproducible retention.

- Load the sample with a sufficiently low constant flow rate to enable good interaction between the sorbent and the analyte of interest and ensure quantitative retention.

- Remove any trace of washing solvent that could disturb the future elution or compromise the post SPE steps (e.g., removal of any water trace in case of GC analysis)

- Elute the analyte(s) of interest efficiently for high recovery (accuracy) by using the lowest volume of elution solvent possible.

In food safety, the wide range of sample viscosity and volumes makes manual control of these paramaters challenging. Automation brings sample-to-sample consistency and reproducibility for these key parameters.

Increased productivity

A general rule for sample preparation is that the more complex the matrix is, the more extraction and isolation steps are needed and fastidious, but it also means greater risk of human error. Therefore, automating long processes helps free up technicians' time for other tasks and minimizes their exposure to hazardous materials. These are additional added benefits to SPE automation.

Furthermore, with the development of globalized food trade, increased pressure is exerted on the food safety labs to produce traceable data for higher sample throughput.

Choosing a fully automated SPE system can be a great option when sample preparation becomes a bottleneck in the lab, especially with complex matrixes.

Choosing the Best SPE Automation Approach

A good automation approach must balance the throughput (number of samples processed by a unit of time), the capacity (number of samples processed per run), the traceability, and keep a low total cost of ownership of the system.

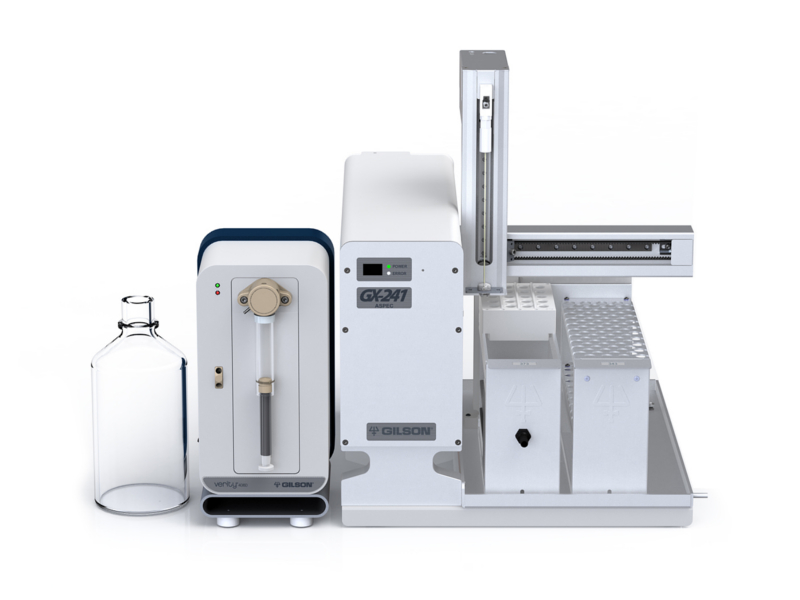

We offer three fully automated SPE systems with different capacities and/or throughput to address these issues: the ASPEC® 241 system, the ASPEC® 271 system, and the ASPEC® 274 system.

Their mobile rack technology allows for a fully automated SPE protocol, which can also be performed overnight to increase productivity regardless of the complexity for multi-dimensional SPE or fractionation. The use of multi-probe systems capable of processing several samples in parallel, such as the ASPEC 274, increases sample throughput in the lab.

For manual SPE methods that are performed using a vacuum manifold to push liquid through the solid phase, we offer a a robust solution that allows you to apply positive pressure into the cartridge. This method is widely used in automated SPE instruments today because of the numerous advantages for flow rate consistency and the drying step's control regardless of the viscosity or volatility of liquids.

Gilson, the pioneer of this principle, continues to promote this option for its automated solutions and its manual SPE system, the ASPEC® Positive Pressure Manifold (PPM).

If productivity and throughput are essential in your automated SPE approach, you must choose an automated SPE system capable of accurate and reproducible control for the critical parameters highlighted above. Our ASPEC instruments are an ideal choice in the lab as it features a precise syringe pump that ensures the accuracy of your volumes. It also helps to achieve consistent SPE results while overcoming bottlenecks in the lab associated with sample preparation.

Start Transferring Your SPE Protocol to Automated Systems from Gilson

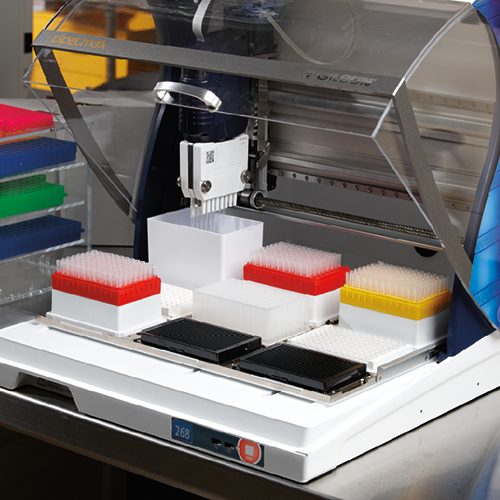

To maintain productivity and performance in your automated SPE protocols, the software associated with your system must allow for complete control of all SPE workflow parameters. Our TRILUTION LH software, designed by scientists for scientists, offers a drag and drop feature with predefined SPE tasks. These predefined tasks will help you transfer your manual SPE protocols to your new system quickly and efficiently.

One of the primary benefits of automating SPE protocols is transferring challenging or repetitive tasks to liquid handing systems. Control of SPE automation must remain simple and easy to use while allowing for data traceability.

For more information about automating SPE for food safety analysis, reach out to a Gilson representative today.

Trusted Solutions for Reliable Extraction

From compound isolation from biological, food, or environmental matrices to protein-protein interaction studies, we have the extraction solution you need to advance your science. From manual to automated solutions, choose from the most comprehensive range of instruments and consumables in the market that have unmatched reliability.

LEARN MORE